|

|

|

Nitrile Glove Production Line

1 Production Line Application; 2 Main Equipments; 3 Process Flow; 4 Technical Parameters

1 Production Line Application:

Suitable raw material: butadiene and acrylonitrile are polymerized by emulsion polymerization.

Pure nitrile: nitrile rubber (NBR) is a synthetic material which is polymerized by butadiene and acrylonitrile monomers. It is mainly prepared by low temperature emulsion polymerization.

Composite nitrile: nitrile latex; Mixed nitrile: nitrile PVC.

Production: nitrile gloves mixed nitrile gloves

| Compared with disposable latex gloves, nitrile gloves have the advantages of: acid resistance, alkali resistance, oil resistance, non-toxic, harmless, tasteless, anti-static, not easy to aging and no protein. 1. Wearing more comfortable, good adhesion and flexible operation; 2. Not sticky, not easy to aging, can be used repeatedly; 3. Anti static; 4. This is also the reason why nitrile gloves can be more widely used in biology, chemical industry, food, medical, electronics, precision instruments, scientific research, laboratories, beauty salons and other industries, as well as housework and daily protection. |

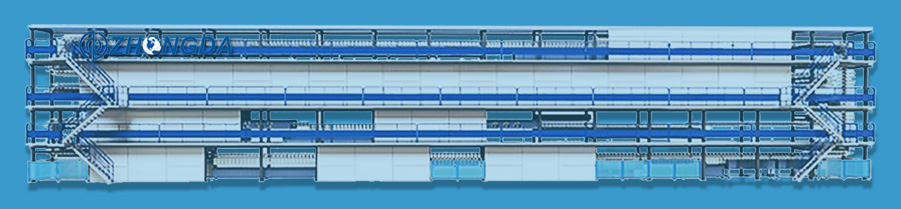

2 Main Equipments:

1 机架;2 手模输送机;3 手模洗槽;4 垂滴槽;5 毛刷轮;6 凝固剂槽;7 乳胶槽;8 烘箱;9 卷边机;10 氯洗槽;11 PU槽;12 脱模机

|  |

Nitrile Glove Production Line | Nitrile Glove Production Line |

|  |

Nitrile Glove Production Line | Nitrile Glove Production Line |

|  |

Nitrile Glove Production Line | Nitrile Glove Production Line |

|  |

Nitrile Glove Production Line | Nitrile Glove Production Line |

|  |

Nitrile Glove Production Line | Nitrile Glove Production Line |

插入视频

视频: |

3 Production Flow:

1. Washing the mold: Wash the ceramic mold with clean water;

2. Immersing in calcium water: Immerse the ceramic mold in calcium water to evenly distribute calcium ions on the surface of the ceramic mold;

3. Drying: Drying the ceramic mold soaked with calcium water;

4. 浸乳胶,将烘干后的陶瓷模具浸在乳胶内,使陶瓷模具表面覆盖一层乳胶形成乳胶手套;

5、卷边,将步骤4种的陶瓷模具通过卷边机构,对乳胶手套的开口处进行卷边处理;

6、烘干,将卷边后的乳胶手套烘干,去除乳胶手套表面的水分;

7、沥滤,将烘干后的乳胶手套在热水中浸泡后取出;

8、干燥硫化;

9、水冷,将步骤8的乳胶手套浸在冷水中冷却;

10、脱模,将乳胶手套从陶瓷模具上脱下,完成乳胶手套的生产。

4技术参数:

仅供参考,以实际订购为准。